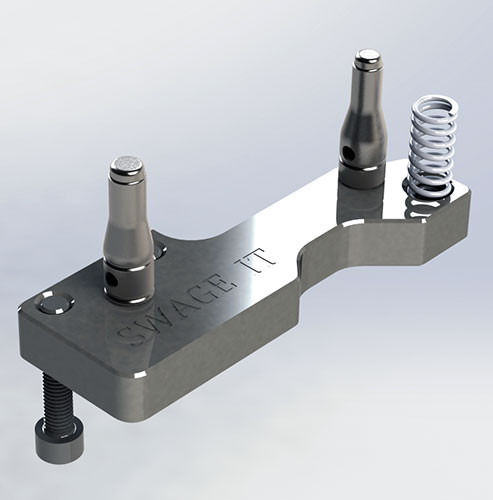

We are proud to announce the Swage It Primer Pocket Swager for the Dillon XL750 bullet press. Included is the mount, small and large primer swages, and mounting hardware. Everything that you need to swage .223, .308 or any other calibers that utilize small or large primers. Also all of our products ship for free within the US.

Below are the list of benefits using our swage.

- Machined from billet aerospace stainless steel

- Properly re-sizing primer pockets cannot be achieved by a spring loaded swage as it will get stuck in the primer pocket. That is why ours is frame mounted.

- The easiest setup available

- Engineered to properly swage on a Dillon XL750

- Our swage actually re-sizes the primer pocket and adds the correct fillet

- Use your case feeder and swage over 800 rounds per hour

- Proudly made in the USA

- Our swagers are protected by U.S. Patent No. 9,494,398.

10 Reviews Hide Reviews Show Reviews

-

Swager

Great swager!.. lightning fast delivery!

-

Swage It XL750 combo

A must have tool. Works exactly as in the instructional videos.

-

Not impressed

Easy to install. Innovative. But results not impressive. After using it, primer pockets still very tight on go/nogo tool. Shoulder barely chamfered if at all. Lyman hand tool does a much better job but incredibly slow.

-

Great product

This is the best solution for swaging military brass I have used in almost 20 years of reloading. With the addition of this and an on-press powered trimmer and a decapping die, I can completely process brass in one pass through my xl750. Such a time saver!

-

Wish I had bought it sooner.

Having been swaging using a variety of other methods, between single stage press and standalone options, this has been the most efficient and most consistent method I've found to swage my brass. I wish I had bought this sooner, for how easy it's made my life during prepwork. Cannot recommend SwageIt highly enough to others. Very well made, durable design, and easy to install and use.

-

Best Swaging Option Available for Economy of Motion.

I had mine installed and lined up before it had even warmed up to the house from the mailbox. It is a gorgeous piece of machining that installs in literal seconds. I left the screws a little loose, stuck a de-primed piece of brass on it to center it good, and snugged the provided screws down. That simple and you're off to the races. I'm using a case feeder and a decapping station so the process is effortless and VERY productive at making shorter work of this really tedious step in brass prep. I figured out pretty quick that it really makes the process much better if you simply tap the top of the swager button with Imperial wax every so often and you don't have to work yourself at all. Stop overthinking this and buy one.

-

Love It!

Absolutely love this tool. I was actually just about to try to make my own version of this until I saw you guys beat me to it. I Love It!!! Works great, installs easy, fits perfect and does the job well. The first day I had it I swaged 2150, yes that 2150 .223 cases. Now I don't need to use the hand tool. You guys saved me potentially thousands of hours of work by inventing this tool. OUTSTANDING!!!

-

Well made swage.

I have only used it for 3 stake type crimps so far. Swages great. Tested many of my brass with the Ballistics Products primer pocket gauge. Snug, but fits. Perfect. I gave 4 stars because I think the swager is a hair too tall. I have a universal deprimer in spot #1. The dillon xl750 press arm can't go down far enough to fully push the case into spot #1 causing problems. Problems such as bent case mouths when the case mouth crashes into the bottom of the deprimeing die.

-

Swage It on pistol brass

While most crimped primer pockets may be encountered on rifle caliber brass, they are present on pistol caliber brass as well. 9MM being a NATO caliber is a likely candidate. After multiple interruptions reloading 9MM on my Dillon 750 because of primped primer pockets, Swage It proved to be a solution. It installed easily, worked flawlessly. True, it takes two operations, but two cycles through the press beats having to manually take a piece of brass out and externally swage it before returning to the loading cycle. It’s a big asset especially when you pick up range brass.